ERP, shop floor, and manufacturing software that keeps production moving.

Shop Floor Digital helps manufacturers modernize ERP workflows, integrate plant equipment, and build custom software that connects planning, production, and reporting in real time.

Core Services

From ERP configuration to shop floor automation, we focus on delivering stable, measurable improvements that reduce downtime and improve throughput.

ERP Optimization

Custom workflows, reporting, and integrations to align your ERP with real production needs.

Shop Floor Integration

Connect sheet metal equipment and operators with live data: lasers, fiber lasers, turrets, press brakes, deburr, hardware insertion, and assembly.

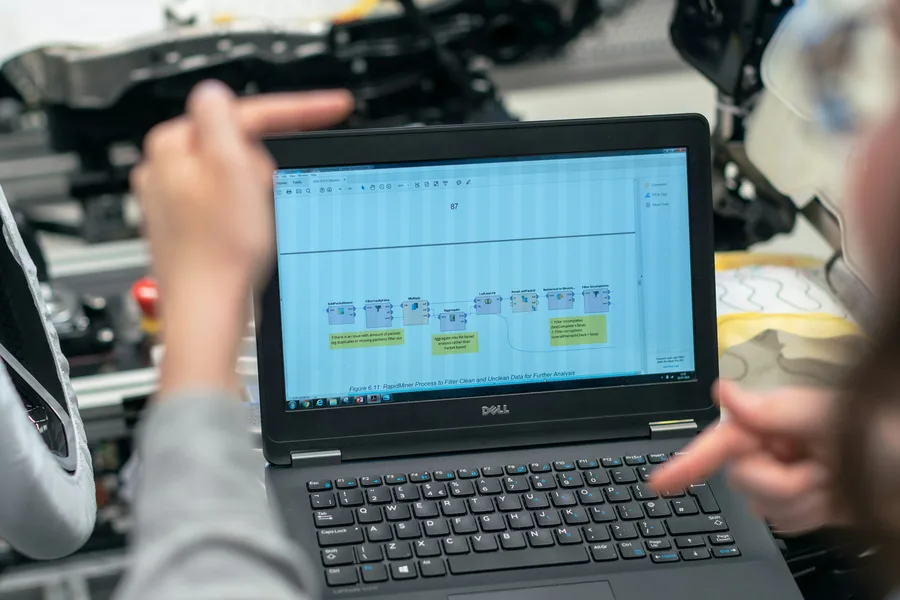

Manufacturing Analytics

Track KPIs, bottlenecks, and inventory flow with clean dashboards and audit-ready reports.

Discovery that turns plant data into performance gains.

We start with a structured exploration of your ERP, equipment, and shop floor workflows to identify throughput constraints, data gaps, and automation opportunities. The result is a clear action plan with measurable wins.

- ERP workflow audit: scheduling, inventory, and reporting accuracy.

- Equipment review: laser, fiber laser, turret, press brake, deburr, hardware insertion, and assembly.

- Shop floor observation: operator handoffs, data capture, and rework points.

- Performance baseline: OEE, WIP, and lead-time checkpoints.

What you get

A practical roadmap that prioritizes automation with the highest production impact.

Why shop floors invest in automation

Manufacturers pursue automation to protect throughput, stabilize labor gaps, and turn shop floor data into decisions. Here are the outcomes we target for every engagement.

Reduce manual handoffs

Connect routing, work orders, and labels to eliminate re-keying and delays.

Improve schedule confidence

Live machine status and WIP visibility keeps promises aligned to capacity.

Protect margin

Track material usage, scrap, and utilization to recover lost profitability.

Automation impact in the real world

Verified results from smart manufacturing and ERP-enabled automation programs.

Sheet metal fabrication expertise that translates to results

Proven work in sheet metal fabrication: ERP customization, shop floor automation, and compliance-driven infrastructure upgrades delivered for production teams.

Food Warming Equipment

ERP and infrastructure modernization

- Customized ERP workflows and reports using PHP, Ext JS, and SQL.

- Built an in-house agile platform to streamline production operations.

- Managed VMware vCenter, Active Directory, and 24/7 manufacturing infrastructure.

- Maintained high-availability SQL Server and MySQL environments.

Alert Tubing Fabricators

Security and compliance enablement

- Implemented secure infrastructure supporting DFARS, NIST 800-171, and ISO9001 compliance.

- Migrated ERP and internal applications with zero downtime.

- Deployed access controls to protect sensitive manufacturing data.

Sheet Metal Fabrication Cell Integration

ERP and shop floor integration

- Integrated ERP job data with laser, fiber laser, turret, and press brake workflows.

- Automated routing, nesting prep, and label printing tied to part outputs.

- Monitored material usage, utilization, and scrap to improve throughput.

Operational focus, not just IT delivery.

We bridge the gap between production teams and leadership, delivering systems that operators can trust and executives can scale. Every engagement blends infrastructure, software engineering, and on-floor process insight.

Production-first design

Solutions are built around throughput, uptime, and operational realities.

Reliable integrations

Stable data flow between ERP, shop floor, and reporting tools.

Security and compliance

Infrastructure built for DFARS, NIST, and ISO-driven environments.

Ready to modernize your plant systems?

Let us map your current workflows and build a plan for dependable, scalable improvements.

Book a Consultation